Use Case: Touchless Torque Measurement on the Sprocket for Electric Motorcycles

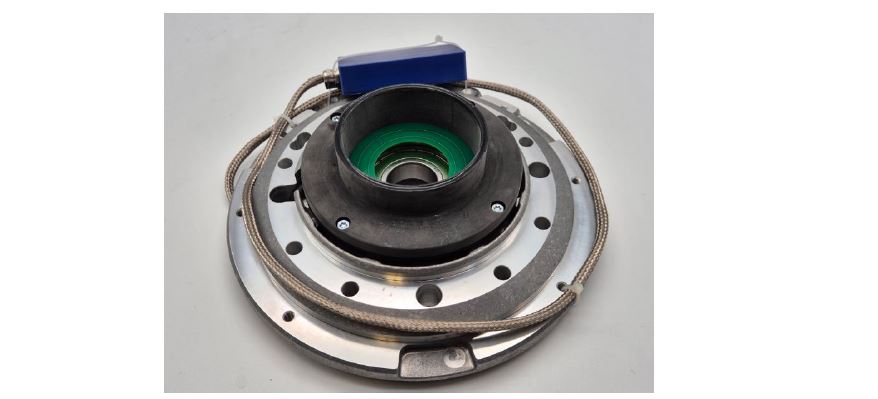

Melectric developed a touchless Torque Measurement Systems for ABM Greifenberger which can be mounted directly inside the Electric engine, all the measurement data and powersupply is integrated wihin minimal space into the Rotor. Designed to withstand the roughest environemt, high tempeature and extreeme EMC noise.

Table of Contents

Introduction

Torque measurement plays a crucial role in the development and optimization of drivetrain systems, particularly in electromobility. Accurately capturing torque in the drivetrain enables an in-depth analysis of power delivery, mechanical losses, and load distribution.

ABM Greifenberger, an innovative manufacturer of electric Drivetrains for industrial trucks, relies on our touchless torque measurement systems to elevate the performance of their vehicles. Melectric Systems developed a Sensor for ABM which provides the possibility to measure Torque on the Rotorpart of the electric Engine, providing high-resolution real-time data with lab grade accuracy up to 0.03%.

Advantages of Torque and Temperature Measurement Directly inside Electric Engines

Measuring torque and temperature directly on the rotor inside an electric engine provides a uniquely accurate view of the real mechanical and thermal behavior of the drivetrain. Rotor-integrated telemetry systems capture the true load and temperature conditions exactly where they occur—inside the rotating assembly—resulting in significantly more reliable data than external sensors or model-based torque estimations. Since the measurement is not influenced by electromagnetic assumptions, current-based estimations, or indirect temperature models, the system delivers a high-resolution and undistorted representation of the motor’s actual operating state.

Direct rotor temperature measurement is especially valuable because thermal hotspots often develop in the rotor long before they become visible at the stator or housing. Telemetry makes these temperature peaks detectable in real time, enabling more accurate thermal design, effective protection functions, and optimized performance limits. The combination of torque and temperature data creates a clear correlation between mechanical load and thermal stress, helping engineers identify the root causes of overheating, efficiency losses, or premature component wear.

At the same time, direct rotor torque measurement significantly improves motor control. Real-time mechanical torque information allows precise load-dependent control strategies, dynamic torque limiting, more efficient regenerative braking, and stable operation during rapid load changes. Since the controller no longer relies on estimated torque values, overall system efficiency and responsiveness increase noticeably.

Rotor-based telemetry also enhances simulation and model validation. Real mechanical and thermal data serve as a reliable foundation to calibrate FEM simulations, thermal models, and digital twins, reducing development cycles and improving predictive accuracy. In addition, continuous monitoring of torque and rotor temperature enables early detection of anomalies such as bearing degradation, increased friction, or misalignment—making predictive maintenance far more effective.

Technical Challenges of Measurement

Measuring torque and temperature directly on the rotor of an electric motor introduces a unique set of technical challenges that require highly specialized Equipment. Unlike external sensors, rotor-integrated telemetry must operate inside the harshest zone of the motor, where extreme mechanical, thermal, and electromagnetic conditions work simultaneously against measurement accuracy and system stability.

One of the most demanding aspects is the enormous centrifugal force acting on the rotating assembly. At high rotational speeds, components experience thousands of g, meaning sensors, electronics, and structural elements must be exceptionally robust, lightweight, and mechanically balanced. Even minor deformation or mass imbalance can lead to vibration, increased bearing loads, or complete system failure.

Thermal stress represents another major challenge. The rotor is exposed to rapid temperature changes and sustained high temperatures caused by copper losses, magnetic fields, and inverter switching. Sensors must deliver accurate torque and temperature values despite material expansion, drift, and long-term aging, requiring high-temperature-resistant materials and advanced encapsulation techniques.

Electromagnetic interference further complicates measurement accuracy. The rotor is surrounded by strong, fast-changing magnetic fields and high-frequency inverter pulses that can distort sensor signals or disrupt wireless data transmission. Reliable telemetry therefore depends on optimized EMC design, shielding strategies, and resilient communication protocols that maintain signal integrity inside this noisy environment.

Space constraints inside the electric motor intensify the technical demands. Telemetry components must fit into very small areas without affecting rotor dynamics, magnetic flux distribution, or mechanical stability. This requires ultra-compact electronics, custom sensor layouts, and precise balancing to avoid unwanted vibrations.

Benefits for ABM Greiffenberger Through Rotor-Integrated Torque and Temperature Telemetry Technology

ABM Greiffenberger can gain significant technical and economic advantages by integrating rotor-based torque and temperature telemetry into their electric motors and geared drive systems. The technology provides deep insights into real mechanical and thermal behavior inside the motor–gearbox assembly, enabling higher reliability, efficiency, and competitiveness.

A key benefit is the ability to measure true torque and rotor temperature directly at the point of load generation. While conventional methods rely on estimation, rotor-integrated telemetry delivers precise real-time data on load cycles, thermal hotspots, and dynamic stress peaks. This reveals how motor and gearbox components interact under real conditions, helping ABM identify losses, reduce thermal stress, and optimize drive design more effectively.

For development teams, this data shortens validation cycles and improves simulation accuracy. Real measurements allow precise calibration of FEM, CFD, magnetic models, and digital twins, reducing prototype iterations and speeding up time-to-market for new drive solutions.

Long-term durability also benefits from early detection of rotor-level thermal overloads, torque irregularities, or vibration patterns that indicate wear. This strengthens series production quality and enables predictive maintenance concepts for end customers, creating additional service value.

Externally, ABM gains a competitive advantage by offering drives validated with real internal data rather than theoretical estimates. As industries demand more efficiency, reliability, and digitalization, telemetry-validated motors and gearboxes position ABM strongly in the premium drive market.

Conclusion and Outlook

Telemetry inside electric motors provides direct access to the real mechanical and thermal conditions occurring within the rotating system—data that cannot be captured through external sensors or model-based estimates. By measuring rotor torque, temperature, and dynamic load behavior in real time, engineers gain a deeper understanding of efficiency, durability, and performance under true operating conditions. This enables more accurate simulations, faster development cycles, optimized control strategies, and reliable predictive maintenance. As electric drive systems continue to grow in power density and complexity, rotor-integrated telemetry becomes a key technology for achieving higher reliability, improved energy efficiency, and smarter, data-driven motor operation.