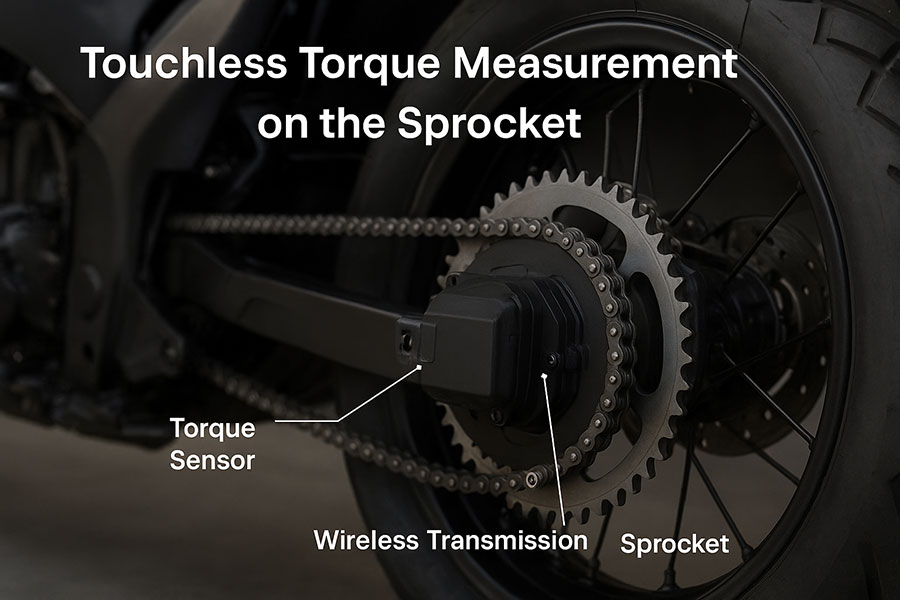

Use Case: Touchless Torque Measurement on the Sprocket for Electric Motorcycles

Melectric developed a touchless Torque Measurement Systems which can be mounted directly on the rearwheel sprocket, all the measurement data and powersupply is integrated wihin minimal space into the sprocket disc. Designed to withstand the roughest environemt on the racetrack.

Table of Contents

Introduction

Torque measurement plays a crucial role in the development and optimization of drivetrain systems, particularly in electromobility. Accurately capturing torque in the drivetrain enables an in-depth analysis of power delivery, mechanical losses, and load distribution.

Stark Future, an innovative manufacturer of electric motorcycles, relies on our touchless torque measurement systems to elevate the performance of their vehicles. Melectric Systems developed a Sensor for Stark Future which converts their conventional Sprocket into a Torque sensor, providing high-resolution real-time data with lab grade accuracy up to 0.1%.

Advantages of Torque Measurement Directly at the Sprocket

A realistic measurement under operating conditions allows for precise torque capture

during real riding situations, ensuring that all mechanical losses between the motor and

the sprocket are accounted for. This contributes to drivetrain optimization by identifying

efficiency losses caused by factors such as chain tension, bearing friction, and material

deformation, enabling fine-tuned torque control that enhances the riding experience.

Real-time data gathered during development and testing processes can be directly

integrated into ride tests to validate simulation models, ultimately improving ride

dynamics through optimized power electronics adjustments. Sampling rates on dynamic

loads exceeding 1 kHz are typical for such applications, ensuring detailed data

acquisition. Additionally, implementing wireless transmission for data transfer allows

seamless integration into the existing drivetrain system with minimal vehicle

modifications.

Technical Challenges of Measurement

Measuring torque directly at the sprocket or

other torque-transmitting discs such as converter discs presents significant technical

challenges, particularly in sensor technology and wireless data transmission.

Mechanical durability is a crucial factor, as these components are subjected to high dynamic loads, including impacts, vibrations, and temperature fluctuations. The use of high-strength materials and an optimized sensor geometry ensures long-term functionality and reliability. Wireless data transmission must operate with minimal latency to provide real-time insights while maintaining energy efficiency for lossless data recording.

Noise levels lower than 0.01% ensure high signal clarity, allowing for precise evaluations. The integration of this measurement technology into existing structures requires compatibility with Stark Future’s control and analysis platforms, ensuring that additional sensor data can be incorporated seamlessly for a comprehensive vehicle simulation. Furthermore, our system offers various output signal options such as 0-5V and CAN Bus with different filter settings and adjustment possibilities. This approach enables torque measurement not only on sprockets but also on converter discs or other rotating elements, expanding its usability across different drivetrain applications.

Benefits of the Measurement Data for Stark Future

The collected torque data offers valuable insights that contribute to various aspects of Stark Future’s electric motorcycle development. By improving motor control, power output can be dynamically adjusted based on real load conditions, optimizing recuperation strategies for enhanced range. Material and design optimization benefits from identifying mechanical stress peaks, which in turn helps increase component lifespan and refine the geometry of sprockets and chainrings for greater efficiency.

The standard temperature range for such systems is -40°C to 125°C, with higher temperature ranges feasible upon request, ensuring adaptability to different operating conditions. Furthermore, a data-driven approach to performance analysis enables the development of new riding modes tailored to individual riding styles, while real-world measurements aid in the simulation and validation of innovative drivetrain concepts.

Conclusion and Outlook

Wireless torque measurement at the sprocket provides a highly precise analysis of power delivery and mechanical interactions within the drivetrain of electric motorcycles. Stark Future leverages this technology to enhance efficiency, performance, and durability in their vehicles. The collaboration between Melectric Systems GmbH and Stark Future exemplifies how innovative measurement solutions can drive the advancement of modern electromobility concepts, delivering tangible benefits in both research and practical applications.