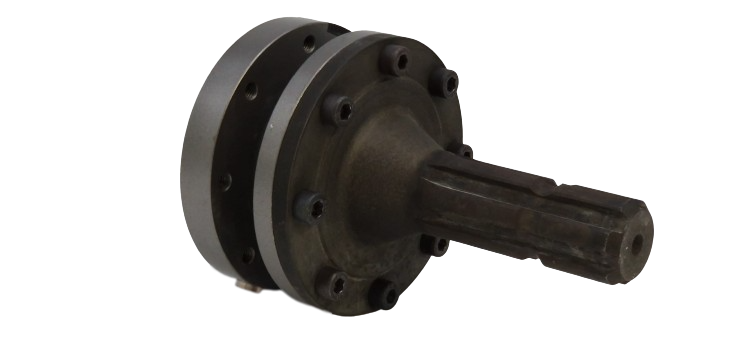

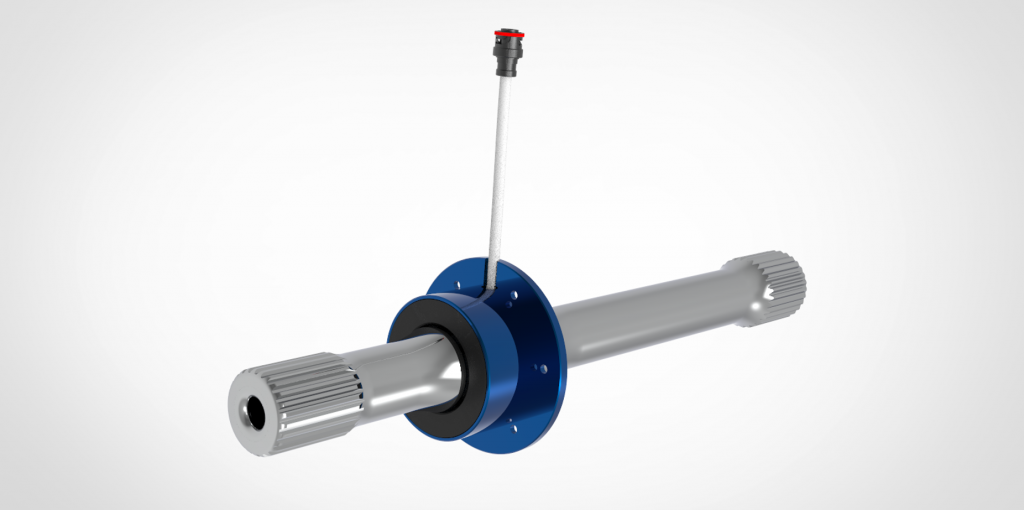

Torque measuring flanges

Universal use for drive train

Technical data

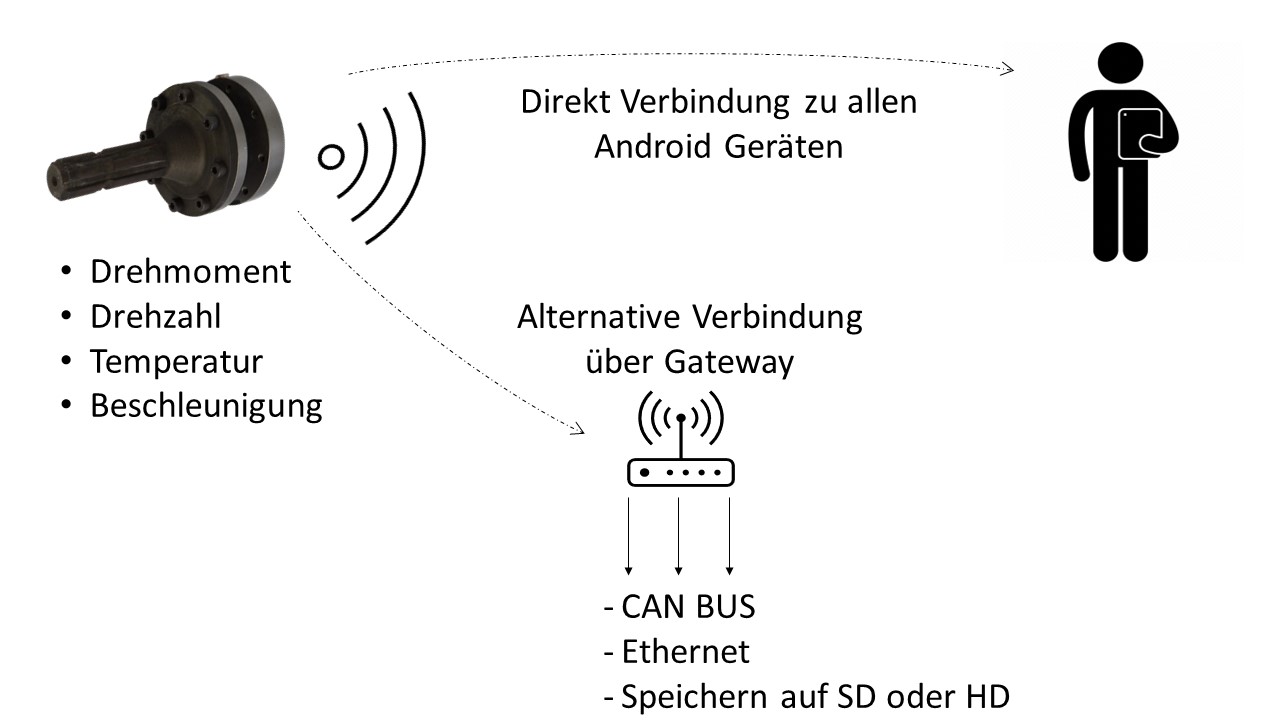

- Wireless connection to Android end devices via APP, no measuring amplifier necessary.

- Measuring ranges: 1000/2500/5000 Nm + customized

- Integrated speed and acceleration measurement

- cutoff frequency: 10 Hz to 500 Hz

- Internal electronics – extremely robust design IP67

- Overall length from. 50 mm axial

- Flange design according to DIN and SAE specification

- Power supply via rechargeable battery for 500 to 1,000 hours runtime

The measuring system is used for:

The determination of torques in the drive train, for example for test benches or in agricultural technology. For determining torques on attachments compatible with adapters for PTO shafts in various sizes.

Torque measuring shaft

The entry class in torque measurement

Simple and convenient handling for many measuring ranges with combined speed and angle of rotation measurement

Technical data

- Measuring ranges from 1 to 1500 Nm

- Available output signals

- 0-5V, +/-5V

- 0-10V, +/-10V

- 4-20mA

- CAN BUS and others on request

- available speed range up to 8000 rpm

- Accuracy up to 0.1% FS

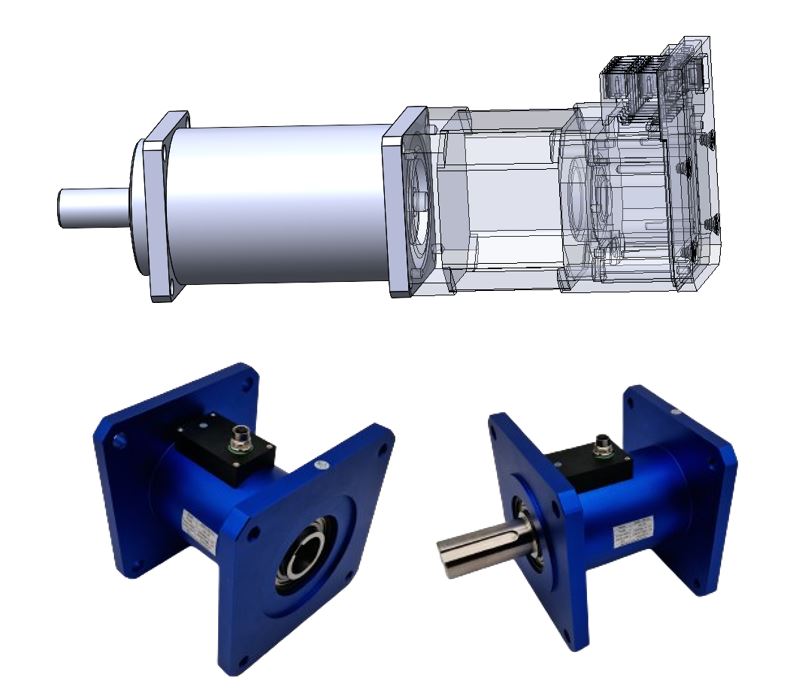

Torque Measurement for Servomotors

For Easy integration directly at the Motor

Simple and comfortable handling for many measuring ranges with combined speed/angle measurement

Technical data

- Measuring ranges from+/- 5 to +/- 300 Nm

- Available output signals

0-5V, +/-5V

0-10V, +/-10V

4-20mA - CAN BUS and others on request

- Available speed range up to 1600 rpm

- Accuracy up to 0.2% FS

- Male and female connection for minimal length

We are happy to adapt the measuring system to your specific needs and requirements. Please feel free to ask us about this.

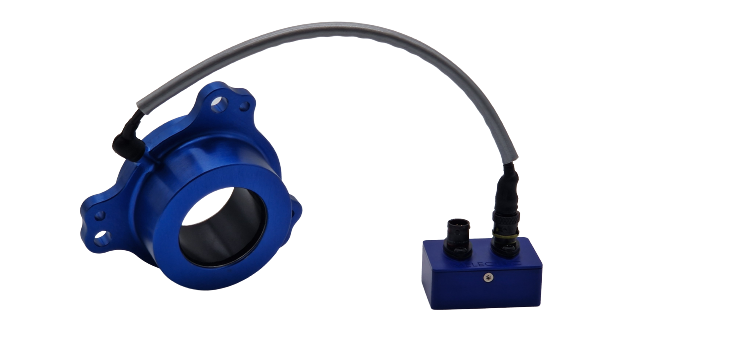

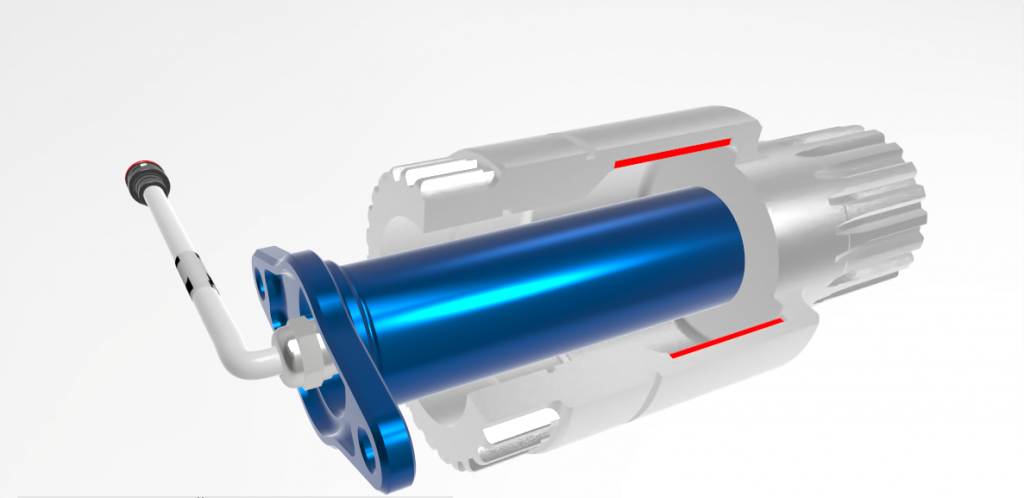

Torque measurement gearbox

installation on cylindrical shaft

Technical data

- Measuring range: typically up to approx. 2,000 Nm

- Signal bandwidth: up to approx. 5000 Hz

- Output signals: CAN BUS and 0-5V (analog)

- Temperature range -40° C to 125° C

- Placement possible in minimum installation space

- Protection class IP68

The measuring system is used for:

Determining the actual horsepower on the track, for example. for on-board engine diagnostics (e.g. misfire, gradual loss of power due to wear). The measurement system is a valuable tool for engine calibration and drivability tuning clutch characterization and control, start-up control, traction control, torque-based engine control or is input variable for transmission efficiency analyses.

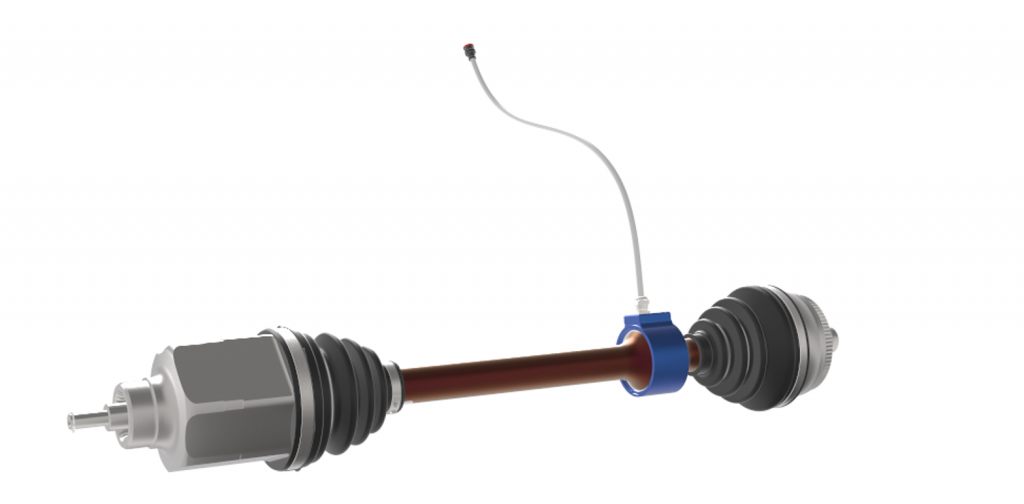

Torque measurement drive train

Application cardan shaft

Technical data:

- Measuring range: typically up to approx. 7000 Nm

- Signal bandwidth: up to approx. 5000 Hz

- Output signals: CAN BUS and 0-5V (analog)

- Temperature range -40° C to 125° C

- Placement possible in minimum installation space

- Protection class IP67

THE DRIVE SHAFT SYSTEM IS USED FOR

- Differential map tuning on the track

- Launch and launch control

- Traction control and/or torque-based engine control

- Closed-loop torque control of the differential in real time

- Evaluation of the aerodynamic efficiency of the vehicle

- The effectiveness of aerodynamic setup changes (e.g. roll-out tests, straight-ahead tests).

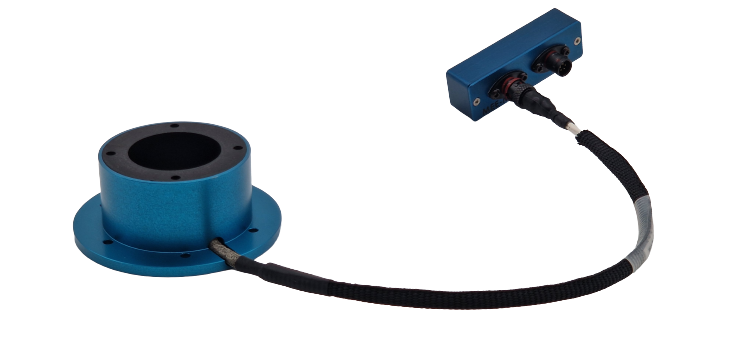

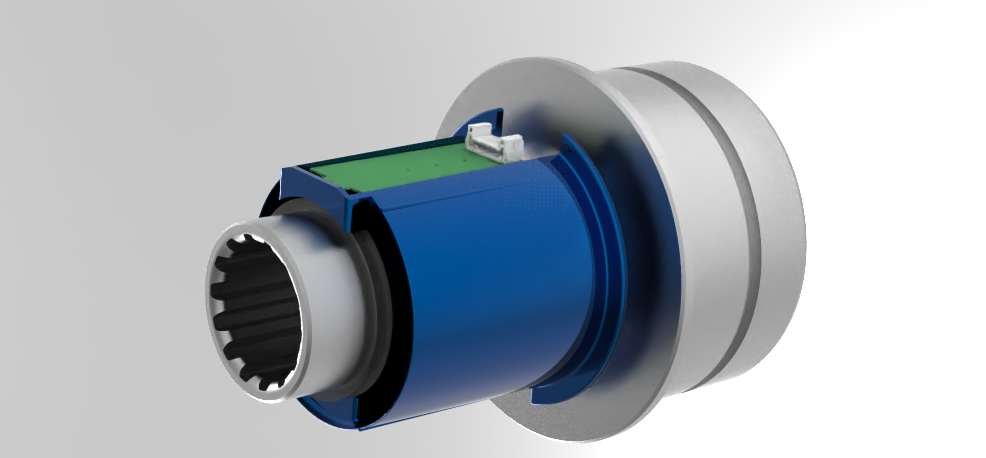

Torque measurement hollow shaft

For gear units with particularly confined installation space

Technical data:

- Measuring range: typically up to approx. 2000 Nm

- Signal bandwidth: up to approx. 5000 Hz

- Output signals: CAN BUS and 0-5V (analog)

- Temperature range -40° C to 125° C

- Placement possible in minimum installation space

- Protection class IP68

We are happy to adapt our measuring system to your specific needs and the available installation space.

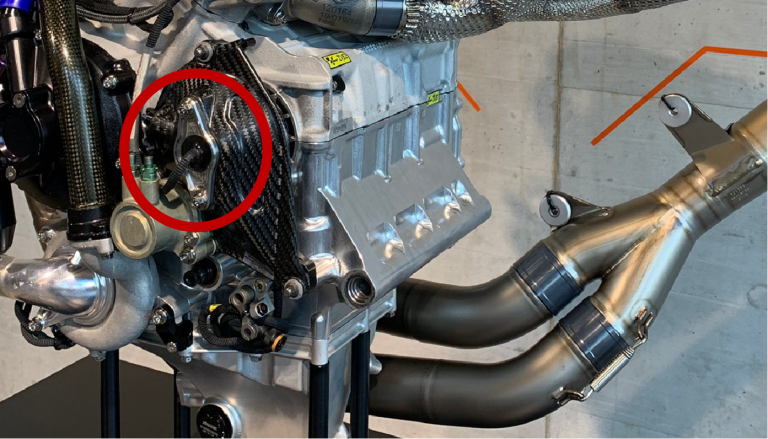

Insert for torque measurement Internal

– Moto GP and Superbike, at the gearbox output (pinion)

– Measurement on Secondary Lay shaft for gearboxes from Xtrax and Sadev for WRC, WRC2 and many more

– All applications with particularly confined installation space

Torque measurement

for customer specific installation space

Technical specification:

- Measuring range up to over 10,000 Nm

- Signal bandwidth: approx. 5000 Hz

- CAN bus or analog output signals 0-5V, 0-10V, +/-5V, +/-10V, others on request

- Temperature ranges from -40° C to 125°C

- Minimum installation space required

- Optionally with speed and acceleration measurement

Use for our customized sensor solutions

Predicitve Maintainance

Power measurement of powertrains

Monitoring of maintenance intervals

Process control, measurement of wear and tear

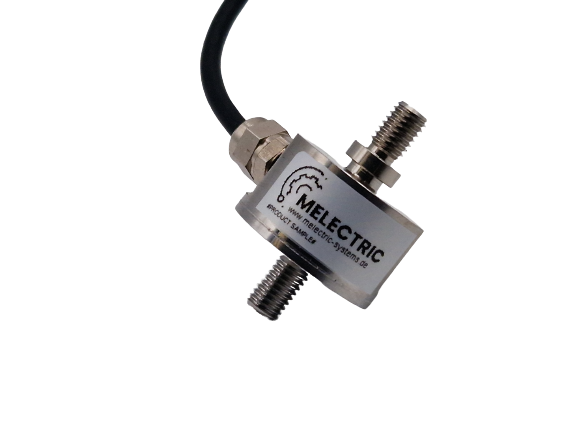

Melectric force sensors

Force sensors for various applications

Technical data

- Force measurement from 0.5 to 1000 kN

- Accuracy up to 0.25%

- for use with external measuring amplifier up to 4 channels

- sampling rate 800 – 1600Hz

- 150% Load limit

- Protection class IP 66, stainless steel housing

- On request – output div. further output signals CAN BUS or Bluetooth

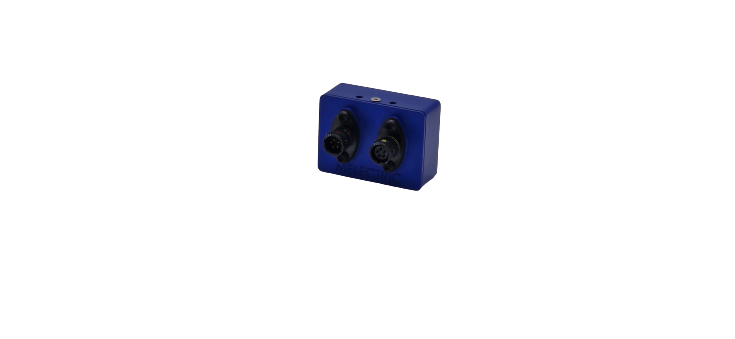

Melectric Smart Mini Gateway

Extension for our Bluetooth products

Easy convenient data transfer and storage for long-term measurements for our Bluetooth devices

Technical data

- Automatic connection with Melectric Bluetooth products (e.g. Melectric measuring flanges)

- Singal transmission to the existing CAN BUS system

- Local data storage on the gateway for long-term measurements.

- Possibility of attaching external antennas for range optimization

- On request – output div. other output signals such as modubus, data output via LTE radio networks and data transmission to cloud networks.

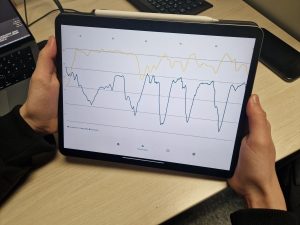

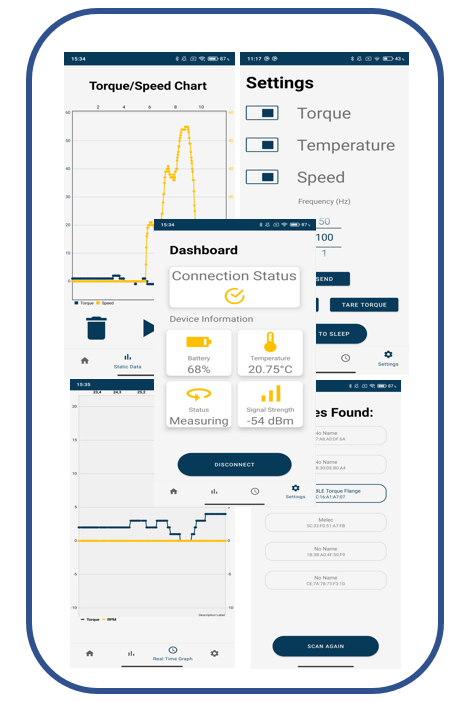

Melectric Wireless – IOT – Solutions

Universal use for various sensors

Melectric Device Manager

- Wireless connection for Windows and Android devices through our included application to Melectric IOT modules.

- Full configuration access to the Melectric modules

- Numerous functions such as reading, saving, or exporting data in other data formats

Melectric BLE IOT – Modules

- Inputs for analog and digital signals

- Numerous configuration options

-

- Different power modes

- Selectable sampling rates

- Configuration or switching on/off of individual channels

- optimized for minimum power consumption

Power supplies

- We offer different options of power supply for our modules.

- We are also happy to provide you with a customized solution. -talk to us.

Connect all different Type of sensors with our module and mobile application

Wide spectrum of possible applications

Our solution enables precise measurement in a high torque range from 1 Nm to several thousand Nm. Since no additional components are mounted on the shaft itself, measurements are possible up to speeds of 300,000 rpm. Typical measurement accuracy is 1% FS, signal bandwidth is typically 1 to 2 kHz, but can be increased to over 25 kHz for customer specific applications. In addition, the evaluation electronics enable the acquisition of additional measured values, such as temperature, acceleration or speed. MELECTRIC offers many possibilities of analog and digital output signals (0-5 V, 0-10 V, 4-20 mA, CAN BUS, I2C, UART, Bluetooth, …).

A maintenance-free alternative to conventional torque measurement

Due to the contactless torque measurement, the system works completely wear-free. Even with strong vibrations, shocks, weather influences or temperature fluctuations, it provides reliable and precise measured values. Magnetoelastic torque measurement is thus a robust and at the same time cost-effective alternative to conventional torque measurement.

Copyright © 2021 Melectric-Systems GmbH