Magnetoelastic torque measurement – versatile, long-lasting, value-for-money

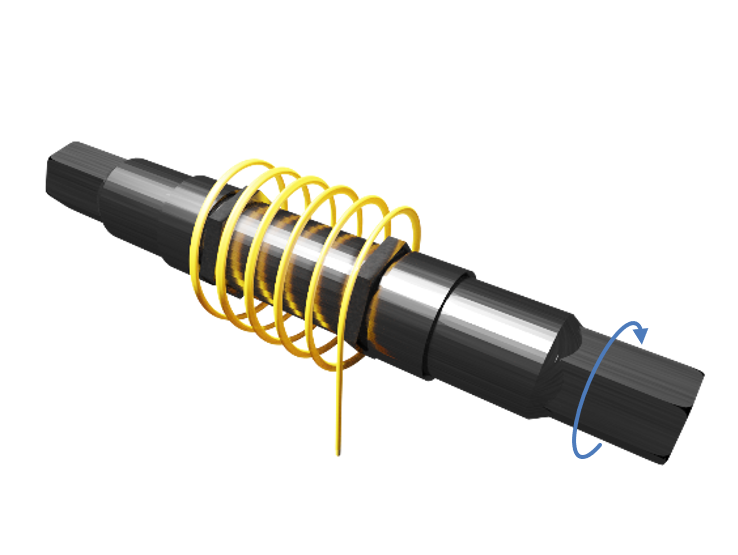

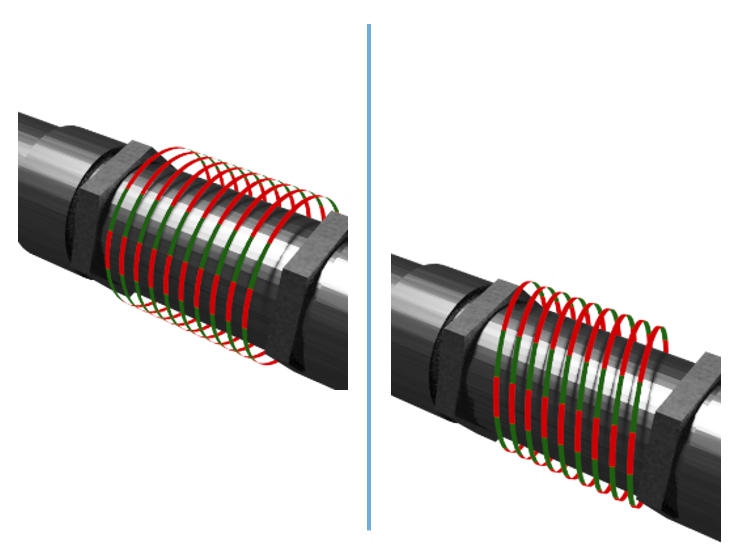

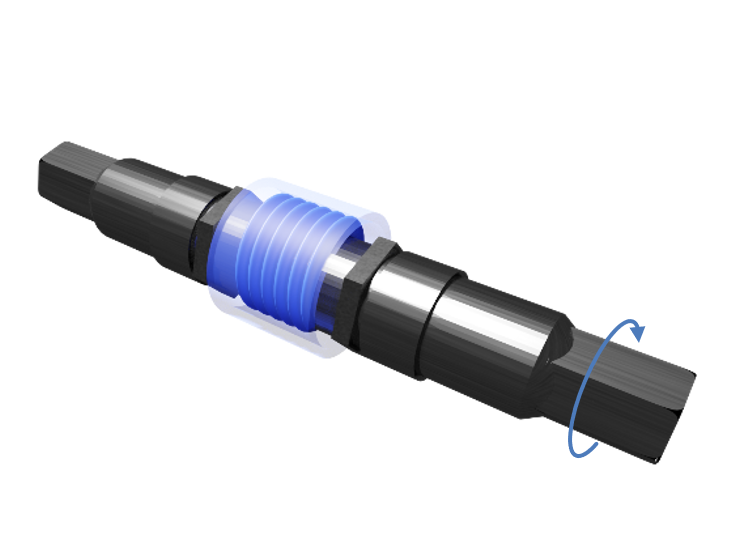

The measurement system refined by MELECTRIC works on the principle of magnetoelastic torque measurement, i.e. that a ferromagnetic material’s magnetic field changes when forces act upon it. These changes are measured and evaluated by the sensor electronics, which are positioned on the shaft that is to be measured without contact, and no additional parts are attached to the actual component transferring the forces. This fully contact-free torque measurement process is what makes magnetoelastic technology unique.

No changes to the shaft

The measurement method is based on the magnetisation of the shaft. Shafts made from a variety of different ferromagnetic DIN or standard materials are suited to this method. We are happy to offer advice on which materials to use. The magnetisation process that we have developed does not alter the shaft’s geometry, material properties, or surface finish. The magnetisation is only performed once. From then on, lifelong torque measurement is possible without any ageing effects.

Magnetoelastic torque measurement made by MELECTRIC

MELECTRIC has made significant refinements to the magnetoelastic torque measurement process. The various additional manufacturing steps help the system to achieve an especially high level of process stability. Our contactless torque measurement solution is therefore market-leading when it comes to sensor precision, offers extremely high long-term stability, and is not sensitive to coatings of the shaft, as even the manufacturing process takes place entirely contact-free.

Advantages of our technology

Surrounding

Extremely high robustness

The magnetic field remains stable throughout the lifetime of the component.

Resistant to oil, excellent vibration resistance.

Usable up to approx. 180 °C depending on the positioning of the electronics.

No additional parts are attached to the measuring body.

MEASUREMENT

Accuracies of up to 0.1% are possible, depending on the surrounding conditions.

Very high signal resolution up to 25 kHz with very low attenuation as e.g. glue joints are omitted.

All common digital and analogue output signals are possible.

The typical accuracy is about 1% FS.

Excellent scalability with low investment and unit costs due to low system complexity and high process stability.

Wide spectrum of possible applications

Our solution enables precise measurements to be taken within a high torque range, from 1 Nm to several thousand Nm. As no additional components are applied to the shaft itself, it is possible to take measurements at rotation speeds of up to 300,000 rpm. The measurement accuracy is typically 1% FS and the signal bandwidth is usually 1 to 2 kHz, but can be increased to over 25 kHz for customer-specific applications. In addition, the evaluation electronics makes it possible to measure additional data, such as temperature, acceleration, and rotation speed. MELECTRIC offers many different options in terms of both analogue and digital output signals (0-5 V, 0-10 V, 4-20 mA, CAN BUS, I2C, UART, Bluetooth,…).

A maintenance-free alternative to conventional torque measurement

The system is completely wear-free as a result of the contactless torque measurement. Even in the event of strong vibrations, impacts, weather effects and temperature fluctuations, it continues to deliver precise and reliable data, demonstrating that magnetoelastic torque measurement is both a robust and affordable alternative to mechanical torque measurement.

| Angular misalignment | Strain gauges | Magnetic (Melectric) | |

|---|---|---|---|

| Contactless | Yes, but a measurement can only be taken when the shaft is rotating | No, or only with the aid of technical equipment, such as telemetry or slip rings | Yes, without limitations |

| Rigidity | Very “soft” or elastic shaft required – problematic for dynamic control processes or applications that are sensitive to resonance | Limited (dependent on torsional strain). The emission of signals in the frequency spectrum over 1.5 kHz is impeded | Very wide range of measurement body rigidities possible |

| Size | Length:diameter ratio of around 5:1 required = long axial design | Inductive power supply and telemetry impede installation and require large application surfaces with respect to the measuring shaft | Minimal installation space: axial shaft lengths < 20 mm; radial installation space for the electronics = 5 mm. High degree of flexibility in design of housing and shaft |

| System run-time/signal bandwidth | Typically up to 0.5 kHz | Typically up to 1.5 kHz | Typically 1 – 2 kHz Special applications up to 25 kHz |

| Can be installed radially | No | No | Yes |

| Long-term stability | Yes | The bonded areas of the strain gauges can cause problems, especially if affected by the temperature | Yes |

Imprint | Privacy Policy | Cookie Policy

Copyright © 2021 Melectric-Systems GmbH