Use Case – High precision Telemetry for use in Electric Motors

Melectric developed a touchless Torque Measurement Systems for ABM Greifenberger which can be mounted directly inside the Electric engine, all the measurement data and powersupply is integrated wihin minimal space into the Rotor. Designed to withstand the roughest environemt, high tempeature and extreeme EMC noise.

Touchless Torque Measurement on the Sprocket for Electric Motorcycles

Discover how touchless torque measurement directly on the sprocket delivers high-precision, real-time drivetrain insights for electric motorcycles. Ideal for performance optimisation, testing, and advanced e-mobility development.

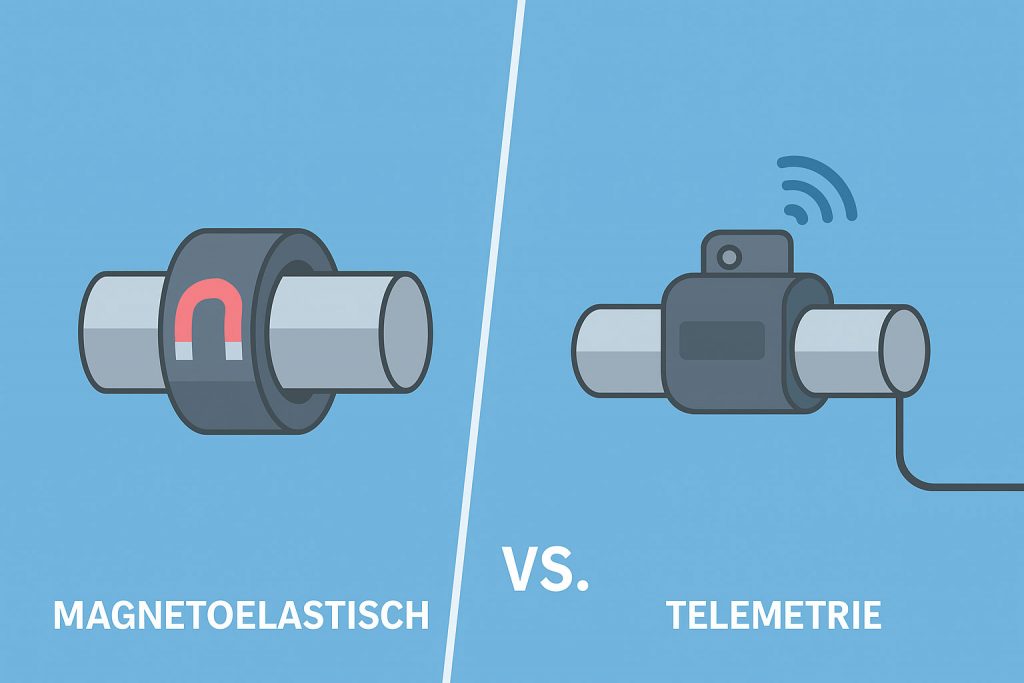

Vergleich: Magnetoelastische Drehmomentmessung vs. Telemetrie

Entdecken Sie den Unterschied zwischen magnetoelastischer und telemetrischer Drehmomentmessung. Erfahren Sie, welches Messverfahren präziser, robuster und besser für Ihre Anwendung geeignet ist.

Was ist ein berührungsloser Drehmomentsensor?

Entdecken Sie, wie berührungslose Drehmomentsensoren Drehmoment präzise ohne mechanischen Kontakt messen – ideal für Elektromobilität, Robotik & Industrie 4.0. Hohe Genauigkeit, langlebig & wartungsfrei.

Torque Measurement Usecase: The Advantages of Torque Sensors in Industrial Bolting Processes

Torque Sensor for Manufacturing Process and smart toolings in the industry. In the realm of manufacturing and assembly, the importance of precision in bolting and screwdriving cannot be overstated. As the backbone of product integrity and quality, these processes demand accuracy, reliability, and efficiency. Advanced torque measurement technologies, particularly those developed by Melectric Systems GmbH, are revolutionizing these fundamental tasks. By enhancing the precision and control over torque application, our technology brings a multitude of […]